- Thread starter

- #21

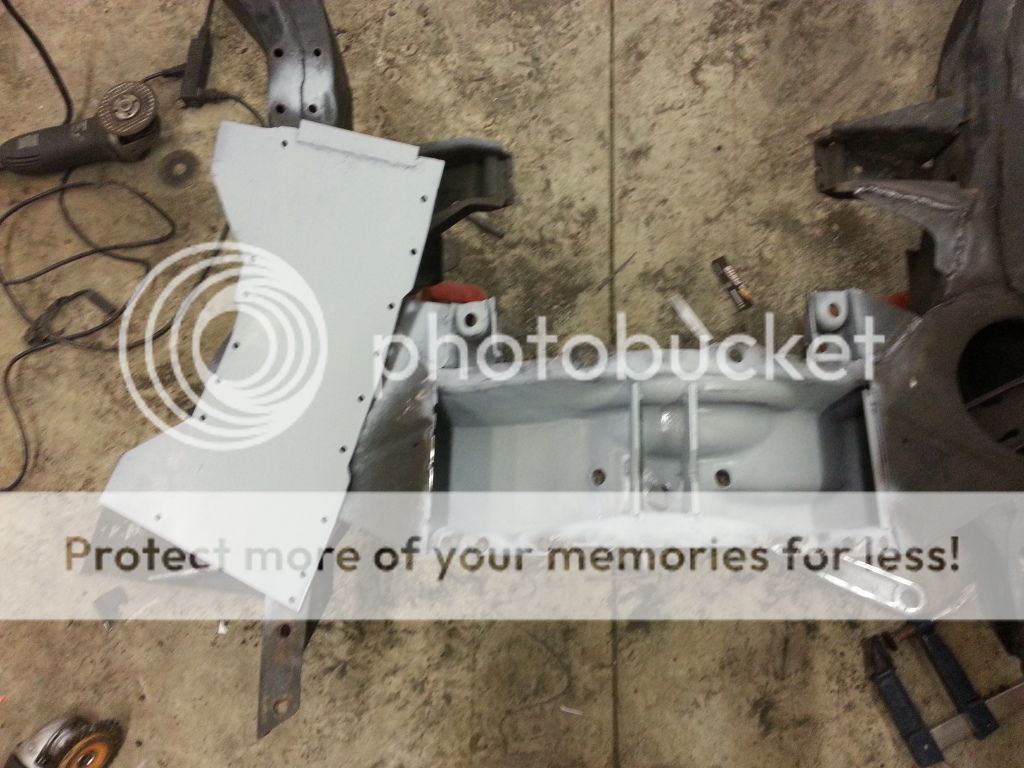

Wow has it really been that long since I have posted here? Time flies when you're busy. Well I have all the suspension parts disassembled and they are pretty much ready for blast and paint. I have turned my attention to the frame. It looked pretty good at first sight but man, when you get into it you find all sorts of stuff. I have lots of pics and I will try to get them posted tonight. I started by making the typical gussets for the front end. Then moved to the back where the big crack was. Did a lot of fab work to make the pieces to fix that area and made it look great....Then covered it up with the original piece. Anyway its no good without pics, so I will say more when they are posted.

T

T

" 67 " is fortunate as he has had his from day one.

" 67 " is fortunate as he has had his from day one.