ya a big hole in that engine comp, from the bottom if you can see the hood mural, well. Ic your Tunnel Plate, shielding and taping is way more organized than mine, looks great. Both do the same mind you. Looking forward to more manny

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nasty1 -383 forged build thread

- Thread starter Manny@Dasilva

- Start date

Are you sure you want to put an engine in there? Think of all the weight you are saving! That motor will just weigh your car down and make it slow.

- Thread starter

- #23

Thanks guys, its a different feeling forsure working on your own vette and seeing it come together . Hope to get in some more parts this week . The clutch and other parts got hung up at customs when they couldn't find the paper work . They should arrive this week , and then I can install the new Tick clutch master  .

.

Engine should be done by the end of the week .

Thx

Manny

Engine should be done by the end of the week .

Thx

Manny

are you going to get it on the dyno this year also or are you going to "park" it after? lovin the updates!!!

- Thread starter

- #25

are you going to get it on the dyno this year also or are you going to "park" it after? lovin the updates!!!

The plan is to get it to the dyno for some tuning . Now if the weather holds out it will be a drive , if not then it will go in the enclosed trailer

Either way some number will be available to post up here

Thx

[email protected]

- Thread starter

- #26

Update

Time for the NASTY report :

Good progress this week .

I was able to get the badges I had made up installed as well as the bezels for the display and some carbon fiber side sails . All had been waiting to get install for about 6 months .

The trans / diff and torque tube are almost done, just need one more bushing and it can be assembled . DTE brace and PFADT rear diff support are also installed .

Yes I know pictures ..........here ya go guys :

Fender badge

Nose emblem

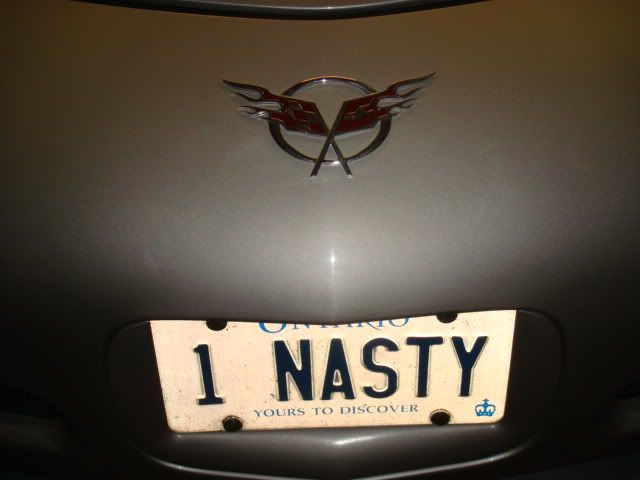

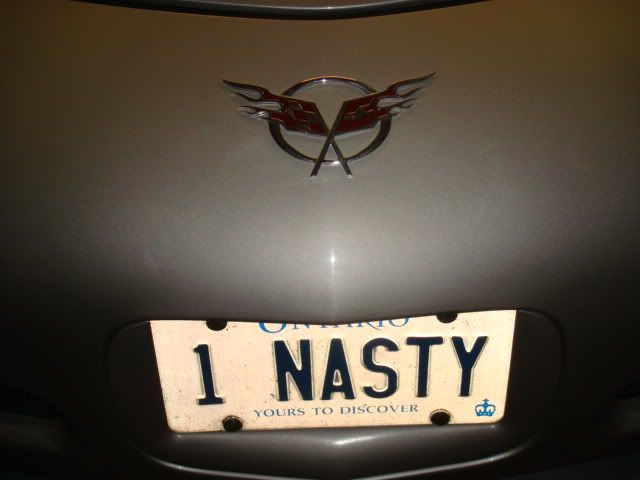

Rear deck emblem

Real carbon fiber sails

Gauge bezels

Ok enough of the bling , here is the go fast stuff ;

Trans with the torque tube removed

Drive shaft from inside torque tube

Notice all the cracks on the rear rubber bushing

Usually we only replace the rear one , but on high HP cars (600RWHP +) we do both , but since I need both as they are both cracked I will be going to solid couplers front and rear .

Here is the rear one installed , my buddy Rich is machining up the other one tomorrow .

Trans & Rear diff painted in a nice blk engine enamel and DTE brace with PFADT rear diff support installed .

The RPS clutch and Tick master are going to be here Tuesday morning .

Still waiting on the engine as my custom Wesco pistons were not ready last week . Piston are to be here Thursday. Going to the chrome shop in the morning to pick up some engine parts I had chromed .

So its coming together slowly but moving in the right direction

Hopefully next week we will be a little closer to dropping the engine back in .

Thx

[email protected]

Time for the NASTY report :

Good progress this week .

I was able to get the badges I had made up installed as well as the bezels for the display and some carbon fiber side sails . All had been waiting to get install for about 6 months .

The trans / diff and torque tube are almost done, just need one more bushing and it can be assembled . DTE brace and PFADT rear diff support are also installed .

Yes I know pictures ..........here ya go guys :

Fender badge

Nose emblem

Rear deck emblem

Real carbon fiber sails

Gauge bezels

Ok enough of the bling , here is the go fast stuff ;

Trans with the torque tube removed

Drive shaft from inside torque tube

Notice all the cracks on the rear rubber bushing

Usually we only replace the rear one , but on high HP cars (600RWHP +) we do both , but since I need both as they are both cracked I will be going to solid couplers front and rear .

Here is the rear one installed , my buddy Rich is machining up the other one tomorrow .

Trans & Rear diff painted in a nice blk engine enamel and DTE brace with PFADT rear diff support installed .

The RPS clutch and Tick master are going to be here Tuesday morning .

Still waiting on the engine as my custom Wesco pistons were not ready last week . Piston are to be here Thursday. Going to the chrome shop in the morning to pick up some engine parts I had chromed .

So its coming together slowly but moving in the right direction

Hopefully next week we will be a little closer to dropping the engine back in .

Thx

[email protected]

Last edited:

It'll be a shame to cover up all those parts with the car eventually

[mob][/mob]

[mob][/mob]

There are not too many original parts on the Nasty it seems anymore!

Good job Manny I am sure she will be a beast when done.

Good job Manny I am sure she will be a beast when done.

- Thread starter

- #29

There are not too many original parts on the Nasty it seems anymore!

Good job Manny I am sure she will be a beast when done.

Hey Greg, just the carpet and seats

Yes, and I thought you where changing them too?

That is quite the brace! Do you notice more noise with the solid couplers? I imagine the response would be a little sharper with them? Can't Wait!!!!!

- Thread starter

- #32

Yes, and I thought you where changing them too?

The seat's will at some point be swapped out for a set of Caravaggio's , but this year . Maybe next year

- Thread starter

- #33

That is quite the brace! Do you notice more noise with the solid couplers? I imagine the response would be a little sharper with them? Can't Wait!!!!!

Riley the brace helps to keep the rear drive train from torque loading and should help to stiffen things up a bit . The couplings are a better to go than rubbber thats for sure . There should be no extra noise from either of these parts . Of the ones I have installed , we have had very positive feed back.

Thx

[email protected]

Very cool! I was just trying to figure out the purpose of GM using the rubber couplers over solid ones? Reduced shock loading between the engine and transmission? Maybe they were just cheaper. I like the idea of the solid couplers.

- Thread starter

- #35

Very cool! I was just trying to figure out the purpose of GM using the rubber couplers over solid ones? Reduced shock loading between the engine and transmission? Maybe they were just cheaper. I like the idea of the solid couplers.

BMW's use the exact same part , as a matter of fact they are made by the same manufacture . Some guys have gone with the M3 ones , but it makes no difference and they are the same as the ones used by GM .

Thx

Manny

I am going with the same DTE brace with PFADT rear diff support with my clutch change next year.

Looking forward to some feedback on these parts, Manny get that thing on the road before the snow comes!

Looking forward to some feedback on these parts, Manny get that thing on the road before the snow comes!

I am going with the same DTE brace with PFADT rear diff support with my clutch change next year.

Looking forward to some feedback on these parts, Manny get that thing on the road before the snow comes!

Greg, Manny installed both of those braces as part of my SC build...the car feels rock solid when launching & shifting...

Thanks Daniel looking forward to getting them installed next year.

- Thread starter

- #39

Ok the clutch finally showed up and its a bute .

Trans and torque tube is all back together now with the new solid couplings.

C6Z06 shift box with soild mounts installed + Anti-Venom mod done

Ram clutch slave and Tick remote bleeder installed

Ah the new RPS Carbon twin light and Tick adjustable clutch master

I will install the Tick clutch master this week and maybe have an engine soon, to put back in

Some bling back from the chromer ( alt bracket and bolts)

Thx for looking

[email protected]

Trans and torque tube is all back together now with the new solid couplings.

C6Z06 shift box with soild mounts installed + Anti-Venom mod done

Ram clutch slave and Tick remote bleeder installed

Ah the new RPS Carbon twin light and Tick adjustable clutch master

I will install the Tick clutch master this week and maybe have an engine soon, to put back in

Some bling back from the chromer ( alt bracket and bolts)

Thx for looking

[email protected]

Last edited:

Looking good so far Manny. Hey quick question Manny, I was thinking of putting LG headers in for a winter project in the garage. Is it a pain in the rear to do??...Or maybe I will come and see you in the spring for the install...Alot easier using a car lift  .lol

.lol

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)