You're probably correct in assuming there are areas behind all those close out panels that would be safe to support the C8 properly. Maybe someone can map them out for us, but in the meantime I wouldn't want to take that chance or guess at it.

If you get a chance to talk to the manufacturer, ask him what kind of jack works with those stands?

I have my C8 up on stands in my unheated garage now. I brought the wheels into my workshop for the winter to ceramic coat them. I feel better knowing those summer only Z51 Michelins won't be subjected to February's sub zero temperatures.

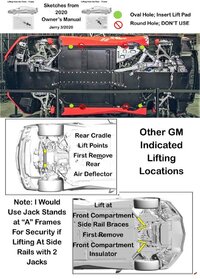

The 4 stands are on the proper jacking points NOW, but it was an interesting adventure getting them there. I was surprised to learn how stiff the C8 chassis actually is, in that, when you jack the car up at one of the rear jacking points, the front wheel on that same side raises as well. I realize with the weight of the engine at the rear, this has a lot to do with it as well. In doing that, you can slide a jack stand under that front jacking point. I then let the jack at the rear down so the car was only sitting on one front jack stand. I then moved my trolly jack over to the opposite rear side, but this time, I jacked the rear end up on the bracket that is attached to the frame, to support the lower control arm knuckle, closest to the rear of the car. Just put a rubber hockey puck on your trolly jack pad so as not to damage that aluminium control arm bracket. (actually, the hockey puck contacts the control arm knuckle as well as the sporting frame bracket when you jack it up there). Plenty strong enough in that location if you ask me... and there is nothing hidden behind close out panels there so you can see all the frame rails. Because this jacking point is a little rearward of the proper jacking location for that side, and again, probably due to the fact that this chassis is so stiff, much to my surprise, the whole car went up! My first thought was... quick, slide a jack stand under the last 3 proper support locations! but before doing so, I went to each corner of the car and leaned on it hard. Then shook and wiggled it. I was shocked at how stable it was! Now, as a disclaimer, GM recommends jacking the car up in the proper locations... but this worked great for me.

The red arrow in this picture shows the general location of the jacking point I used to raise the car.

View attachment 74055