Hey guys,

Been a little while since I posted but I'm getting close to finishing the car.

The first exciting thing is that I tested the tail lights and they worked perfectly! I'm so happy about that because I made over 100 connections when I made all the harnesses and control boxes. Some of you may remember I burned out 8 LED's when I first tested a light and I had to open up one of the lights, identify and order the correct LED's, de-solder the old LED's and solder on 8 new ones. Each LED was 0.5cm² and had 4 connections on them. Here's a YouTube link to the tail lights:

Custom Morimoto tail lights in C3 corvette.

Then I started work assembling the headlights. I found out that the body shop never repaired the one headlight that was cracked by the prop when I asked them to fix it. There was lots of metal around that prop so I simply cleaned and epoxied the crack for insurance. I then found a small section that was missed when they painted. Unfortunately this area was missed when they painted the car but ironically it was never painted when they removed the headlights to paint them again. So I masked off the car and spray them body color and applied a 2k clear over top.

After I finished assembling the headlights I repainted the hood latches, and wiper arms gloss black with a 2k clear to match the rest of the gloss black trim on the car. I've been having a lot of fun electroplating recently so I zinc plated the hood latch springs and the hood strikers. I also made some aluminum hood striker spacers and polished them.

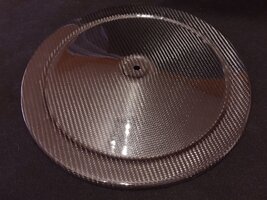

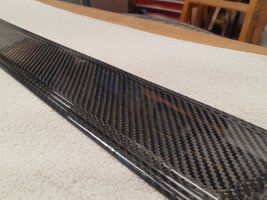

I started to install the wiper cover but ran into some problems. I was going to use velcro to mount the cover however it cause it to sit up to high and contacted the hood. So I marked and drilled holes in the wiper cover and hood surround. I used masking tape in order to protect the paint and provide an area to mark. When I removed the tape it removed a few chunks of paint from the wiper cover. I touched them up and then decided to apply PPF on the cover to protect it. It was second time applying PPF and unfortunately I got some pull marks in it so I decided to remove it. When I removed it huge chunks of paint came off. I reach out to the paint shop and they said it was a delamination due to the wiper cover being primed from the manufacturer and as such they wouldn't warranty the panel. So in addition to the carbon fiber parts I'm making, I will also be making a carbon fiber wiper cover.

I also had the chance to test my electronics all of which work great especially the new stereo. The new speaker box also sounds great and with amplifier I'm getting decent bass out of it. I also tested the speedometer lights since I've painted the insides with duplicolor chrome. I think it gave it a much nicer white look and smoothed the lighting out around the gauges.

I reinstalled the front left and right spoiler.

Lastly, I made an insert for the center console where the cigarette lighter and ashtray are. I made an aluminum panel and I made a small curved box out of plastic and carpeted the inside of the box to hold my phone. I drilled a hole in the other side of the aluminum panel and bought a generic dual USB socket. The socket is made in China so it had some weird brand etched into the aluminum face so I wet sanded and polished the face to give it a custom finish. I then had to take a Dremel and cut out some of the plastic in the center console to fit the new phone holder/USB insert. I am so happy with how this turned out and the phone fits nice and snug in the holder. I just have to repaint the lid for the center console, and run some leads for the USB charger and then this part of the project will be complete.

Coming up I will be testing my alarm system and electric door locks. Provided they work I can finish installing the dash and center console side panels. I'm waiting on some epoxy to start making my carbon fiber parts but I will likely make the molds for the parts this weekend. I'm also waiting on some steering components that are on back order. I'm upgrading the tie rod sleeves for safety and rebuilding the control valve ball stud. I'm also waiting for some new 31 spline rear spindles from Tom's Differentials. I'm going to get the 1/2 studs for added security and will be converting the front wheels to 1/2 studs as well.

Once that all complete homefully I can reinstall my exhaust and see how the exhaust sounds! Then I can get it towed to get fully wrapped in PPF.