As some may have read, as a result of my career, I'm pretty busted up. Doing yard work is difficult for me at best, landscaping is an exercise in pain. With the new house, it was a matter of pay a stupid amount of money to have someone landscape, or do it myself.

Well, I'm not exactly flush, so it had to be do it myself. Wheelbarrow: nope. Can't use that. Shovel: nope, limited use at best. And so it goes with landscaping. I needed a machine to do those jobs for me.

I check the prices on CUT and SCUT tractors. Well, after I finally stop clutching my chest lying on the ground at the dealers lot, new is not going to happen.

Used is just as much a shock, considering how much you have to pay for something older than me and in worse shape.

Ok, this is not that great a situ.

Then I run across "garden" tractors. Smaller than a SCUT, but a little bigger than a ride on lawn tractor/mower. Digging around, I find an old Murray GT on one of the local "for sale" boards:

200 bucks. Briggs18 hp opposed twin. It didn't run, but it turned by hand and stopped hard up against it's compression. The transmission shifted and ran through it's gears. No battery and it was missing the starter solenoid. No cutting deck, but that's not really what this tractor was being bought for. It had the Peerless 820 transmission, which is rated for ground engaging implements (meaning:it's pretty tough).

I get it home, chucked a solenoid and a battery in it. After a little fiddling, it fires up and settles into a decent, smoke free idle. I drive it around the yard and it all seems to work, even with it having been severely neglected.

Well, time to start building it up. First, it needs a stronger frame instead of the OEM stamped form. Some 1/4" flat stock plated to the stamped piece fixes that up nicely:

Now it was at least usable. I needed to level out the new soil, so I used it to drag a pallet over the yard until level:

Worked fine!

Well, I still needed something to move soil/rocks around the yard. I suppose a small trailer would do most of that, but it would still require me using a shovel (and/or my back) to fill it. No, I needed to make a loader for it.

I already had mounted a small winch on the front. I needed to make a way to lift and dump a bucket. The winch would lift it no problem.

I grab an old ATV plow blade for cheap:

Worth buying it, as the steel alone would have cost almost 4 times what I paid for just the blade. Then, start building a bucket:

A little more work and the dumpfeature is done:

I use it like that for a while and it works OK. But it reveals the stamped steel front axle is just roached. So, time for an "upgrade":

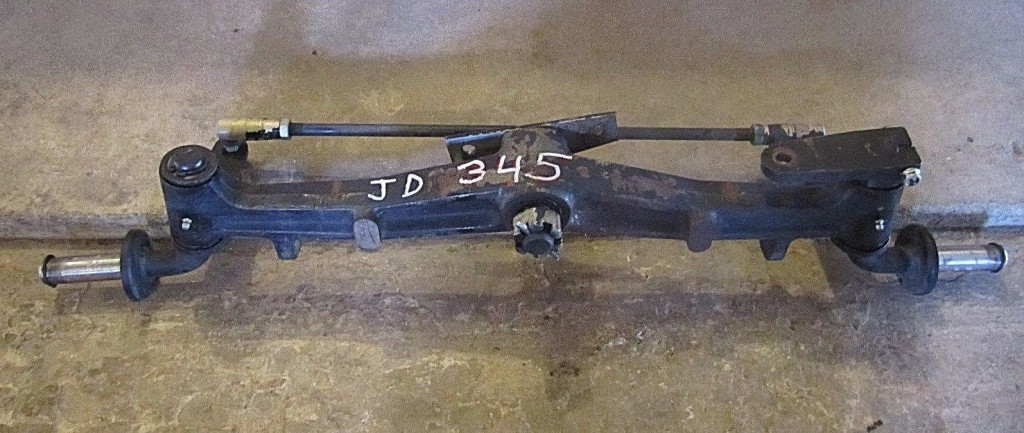

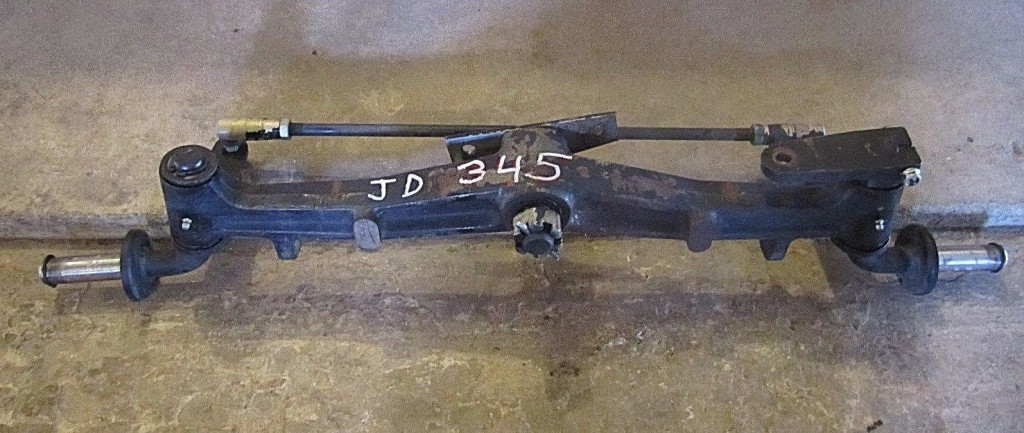

Cast iron JD 345 front axle. Rough as rocks.

out with the old:

in with the new:

I'd already "stretched" the frame, so i moved the front axle further forward:

The extra wheelbase helps with the added weight of the front bucket.

Parts of our yard are off level and the last thing I want it the tractor to roll over on me with a full bucket. So:

Haven't tested it, hopefully I never have to! LOL!

Some wiring work was needed:

I needed more dash real estate, so:

I wanted control sticks, so I went with some that are electric:

Works great!

Time for some lights:

Getting some use out of it:

Well, I'm not exactly flush, so it had to be do it myself. Wheelbarrow: nope. Can't use that. Shovel: nope, limited use at best. And so it goes with landscaping. I needed a machine to do those jobs for me.

I check the prices on CUT and SCUT tractors. Well, after I finally stop clutching my chest lying on the ground at the dealers lot, new is not going to happen.

Used is just as much a shock, considering how much you have to pay for something older than me and in worse shape.

Ok, this is not that great a situ.

Then I run across "garden" tractors. Smaller than a SCUT, but a little bigger than a ride on lawn tractor/mower. Digging around, I find an old Murray GT on one of the local "for sale" boards:

200 bucks. Briggs18 hp opposed twin. It didn't run, but it turned by hand and stopped hard up against it's compression. The transmission shifted and ran through it's gears. No battery and it was missing the starter solenoid. No cutting deck, but that's not really what this tractor was being bought for. It had the Peerless 820 transmission, which is rated for ground engaging implements (meaning:it's pretty tough).

I get it home, chucked a solenoid and a battery in it. After a little fiddling, it fires up and settles into a decent, smoke free idle. I drive it around the yard and it all seems to work, even with it having been severely neglected.

Well, time to start building it up. First, it needs a stronger frame instead of the OEM stamped form. Some 1/4" flat stock plated to the stamped piece fixes that up nicely:

Now it was at least usable. I needed to level out the new soil, so I used it to drag a pallet over the yard until level:

Worked fine!

Well, I still needed something to move soil/rocks around the yard. I suppose a small trailer would do most of that, but it would still require me using a shovel (and/or my back) to fill it. No, I needed to make a loader for it.

I already had mounted a small winch on the front. I needed to make a way to lift and dump a bucket. The winch would lift it no problem.

I grab an old ATV plow blade for cheap:

Worth buying it, as the steel alone would have cost almost 4 times what I paid for just the blade. Then, start building a bucket:

A little more work and the dumpfeature is done:

I use it like that for a while and it works OK. But it reveals the stamped steel front axle is just roached. So, time for an "upgrade":

Cast iron JD 345 front axle. Rough as rocks.

out with the old:

in with the new:

I'd already "stretched" the frame, so i moved the front axle further forward:

The extra wheelbase helps with the added weight of the front bucket.

Parts of our yard are off level and the last thing I want it the tractor to roll over on me with a full bucket. So:

Haven't tested it, hopefully I never have to! LOL!

Some wiring work was needed:

I needed more dash real estate, so:

I wanted control sticks, so I went with some that are electric:

Works great!

Time for some lights:

Getting some use out of it:

Last edited: