Continuing with testing on our mule , here is what is up next

.

Oil catch can & clean side oil/airseparator tech discussion.

AT THE BOTTOM BELOW ARE PICTURES OF CS CATCH CANS. SINGLE CHECK, DUAL CHECK, CLEAN SIDE SEPARATOR AND MONSTER II CATCH CAN

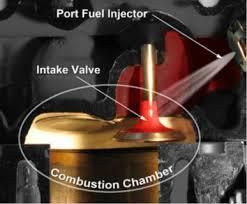

There have been in several threads providing all the technical information including pictures, video, dyno graphs, etc. to educate all on properly caring for these new GDI engines and what happens if not cared for properly, and a large part of this is matching the correct air/oil separating system for your vehicle. Here we will list what you need for your model and options as a guide to help all to not purchase the wrong system. It is important to understand a model of catchcan that may have worked well with a port injection engine, will NOT be sufficient for a GDI engine as there is no longer fuel spraying on the back sides of the valves to keep them cool and deposit free like port injection did as shown here:

This constant shower of detergent fuel has kept intake valves deposit free for the past 20-25 years and the premature wearing of valve guides had gone the way of the dinosaur (so we thought) unlike the earlier carbureted engines had where at 40-50k miles a rebuild was needed (at least a valve job). Now that no fuel touches these valves with GDI:

GDI engines have brought this back with a vengeance, and several times the severity of carbureted engines as they still had some fuel passing the valves to help keep deposits at a minimum. You can also see that all in tank fuel additives are now a pure waste of $ as they cannot do anything to help even the fuel injectors as they now operate at 2000 plus PSI and have little chance of building deposits where these additives did help port injection engines.

Here is an example of a port injection 3.6L GM at 140k miles:

Now the same engine in GDI (begining 2008 GM went to GDI with the 3.6) at 30k miles:

And what happens when a large chunk of these deposits breaks loose after a solvent based upper induction cleaning, or just breaks off on it's own and gets trapped between the valve and seat allowing the piston to make contact and bend the valve:

Look closely at where that chunk broke loose on the left portion of the stem. The engine was run with the bent valve for some time before the dealer tore it down to find the problem. Also note how these deposits have restricted the incoming air flow and causes uneven air distribution when the fuel injectors are still adding the equal amounts of fuel to each cylinder. Some cylinders will run leaner than others, and the carefully designed shape of the valves and ports is now rendered useless.

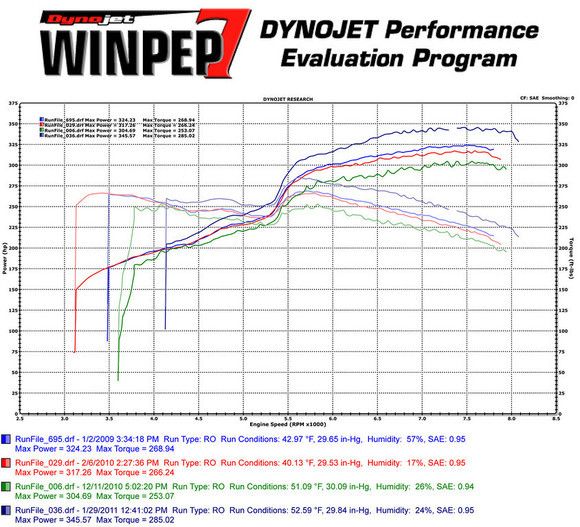

Below is a long term test where the owner documented the power loss as the deposits build on the same dyno, at the same time of year attempting to keep all condition's as duplicatable as possible. Also note the car had app 30k miles on before the first dyno, and then a crushed walnut shell media blasting service was performed and look at that last run after the cleaning:

Also, these hard abrasive particles are drawn up into the valve guides with every cycle and are wearing the guide out of spec by as little as 25-30k miles. This needs to be addressed as soon as you take delivery of the car to prevent any of this from happening. And this video of a new LT1 C7 at 5500 miles shows, wear has already begun to the guides:

You Tube

You Tube

So, preventing this is not difficult if done from the start.

The LT4 does NOT need the cleanside separator unless you are tracking the car and need that added protection for the dry-sump cleanside. The main reason the LT4 does not need the cleanside and the LT1 does is the LT4 will provide constant crankcase evacuation suction/vacuum as this is provided just up stream of the SC rotors so no matter what operating level, a roots type blower is always providing this suction as it does not provide boost until after the blower and then it is directly into the intake ports. So there is little chance of pressure building to the point of pushing oil laden vapors back through the cleanside and into the main intake air box assy like is seen in the LT1 versions, both dry and wet sump.

If you have a LT1, then as it is naturallu aspirated, any time you accelerate, the intake manifold vacuum drops to zero and no evacuation takes place, so the crankcase will build pressure and it will vent backwards out the cleanside inlet and into your main intake air box assy and ingest via this path.

So the cleanside is needed in addition to the dual valve main separator

Why not defeat/delete the PCV system like some are selling that routes both the clean and dirty sides into a large tank and vent through breathers or open hoses hanging near the ground? Several reasons.

First would be the obvious, it will void your warranty in every case due to this will result in engine damage and premature wear of all internal engine parts from the damaging compounds now left to accumulate in the crankcase as evacuation has been defeated and these compounds are no longer removed.

Will not be legal on the street in any State, and will also fail emissions inspections.

What people need to realize is the PCV system provides several critical functions and only one is emissions related. When the Federal Gov mandated all cars and light trucks have CV systems in the mid 1960's, it was intended to reduce pollution, but what the automakers soon found was the engines that rarely lasted more that 50-60k miles before being entirely worn and in need of a total rebuild, were now lasting 100-150k plus miles and longer. Engineers soon found that when the PCV (positive crankcase ventilation) systems were in use, they were evacuating much more than just the oil mist/vapor. They also were constantly removing the water, unburnt fuel, sulfuric acid, abrasive soot and carbon particles, etc. that were previously left in the crankcase to contaminate the engine oil and further attack and corrode internal parts and flushing them with the filtered clean air entering the opposite bank as the foul vapors were evacuated from (evacuation is NOT venting. Venting can only bring a small fraction of these compounds out with pressure). So, defeating your PCV systems functions by using anything vented will result in engine damage and wear over time period. No possible way it cannot unless you would change oil after every outing, and that is impractical and costly.

Then, if it is a system with 2 hoses hanging down, you must understand how the Venturi Effect works. As air flows past an open hose or tube, it creates suction (this is the Venturi effect). But, since this is never equal, one hose will always become the stringer of the two with suction, and the opposite hose will turn into a vacuum cleaner so to speak and draw in dust/dirt/sand/water and other road debris (just look at how your engine bay gets covered in dust and sand in short order even driving on clean paved roads only) and this can enter the engine causing damage. Then we have to look at the fact that you have now bypassed the MAF sensor, and the factory tune is not going to be commanding fuel trims accurately, and you are also relying on pressure to first build instead of pulling vacuum at all times like the proper system will, so allowing any pressure to build to the point of venting out hoses or breathers will cause among many things, ring flutter. This over time results in "divots" of wear in the cylinder walls as well as on the rings themselves so they eventually do not, and cannot seal properly allowing even more blow-by.

So, for now I'll stop here and open this for questions. Do NOT be afraid to ask questions, your new Stingray is a sizable investment, and the engine is different than any of the previous port injection offerings, and these are things you need to be aware of to get the most with the least issues as far as engine related.

Looks like the same old problems to address with a catch can .

The charger lid off shows the oil accumulation on the blower.

The lid as well is covered .

The solution :

$975.00 installed

Available @ Dasilva Motorsports

.

Oil catch can & clean side oil/airseparator tech discussion.

AT THE BOTTOM BELOW ARE PICTURES OF CS CATCH CANS. SINGLE CHECK, DUAL CHECK, CLEAN SIDE SEPARATOR AND MONSTER II CATCH CAN

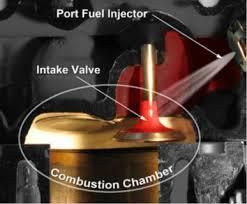

There have been in several threads providing all the technical information including pictures, video, dyno graphs, etc. to educate all on properly caring for these new GDI engines and what happens if not cared for properly, and a large part of this is matching the correct air/oil separating system for your vehicle. Here we will list what you need for your model and options as a guide to help all to not purchase the wrong system. It is important to understand a model of catchcan that may have worked well with a port injection engine, will NOT be sufficient for a GDI engine as there is no longer fuel spraying on the back sides of the valves to keep them cool and deposit free like port injection did as shown here:

This constant shower of detergent fuel has kept intake valves deposit free for the past 20-25 years and the premature wearing of valve guides had gone the way of the dinosaur (so we thought) unlike the earlier carbureted engines had where at 40-50k miles a rebuild was needed (at least a valve job). Now that no fuel touches these valves with GDI:

GDI engines have brought this back with a vengeance, and several times the severity of carbureted engines as they still had some fuel passing the valves to help keep deposits at a minimum. You can also see that all in tank fuel additives are now a pure waste of $ as they cannot do anything to help even the fuel injectors as they now operate at 2000 plus PSI and have little chance of building deposits where these additives did help port injection engines.

Here is an example of a port injection 3.6L GM at 140k miles:

Now the same engine in GDI (begining 2008 GM went to GDI with the 3.6) at 30k miles:

And what happens when a large chunk of these deposits breaks loose after a solvent based upper induction cleaning, or just breaks off on it's own and gets trapped between the valve and seat allowing the piston to make contact and bend the valve:

Look closely at where that chunk broke loose on the left portion of the stem. The engine was run with the bent valve for some time before the dealer tore it down to find the problem. Also note how these deposits have restricted the incoming air flow and causes uneven air distribution when the fuel injectors are still adding the equal amounts of fuel to each cylinder. Some cylinders will run leaner than others, and the carefully designed shape of the valves and ports is now rendered useless.

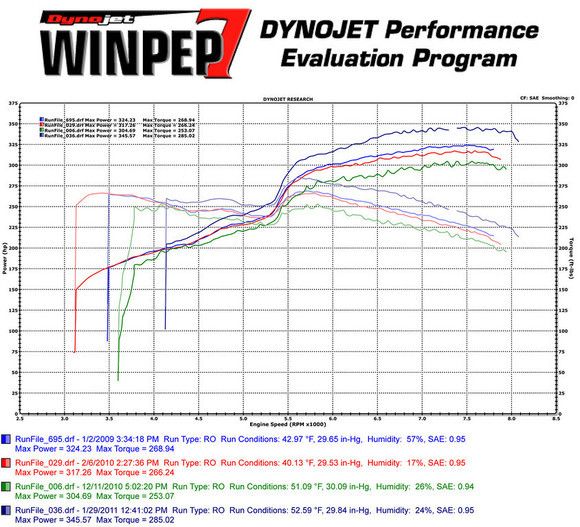

Below is a long term test where the owner documented the power loss as the deposits build on the same dyno, at the same time of year attempting to keep all condition's as duplicatable as possible. Also note the car had app 30k miles on before the first dyno, and then a crushed walnut shell media blasting service was performed and look at that last run after the cleaning:

Also, these hard abrasive particles are drawn up into the valve guides with every cycle and are wearing the guide out of spec by as little as 25-30k miles. This needs to be addressed as soon as you take delivery of the car to prevent any of this from happening. And this video of a new LT1 C7 at 5500 miles shows, wear has already begun to the guides:

You Tube

You Tube

So, preventing this is not difficult if done from the start.

The LT4 does NOT need the cleanside separator unless you are tracking the car and need that added protection for the dry-sump cleanside. The main reason the LT4 does not need the cleanside and the LT1 does is the LT4 will provide constant crankcase evacuation suction/vacuum as this is provided just up stream of the SC rotors so no matter what operating level, a roots type blower is always providing this suction as it does not provide boost until after the blower and then it is directly into the intake ports. So there is little chance of pressure building to the point of pushing oil laden vapors back through the cleanside and into the main intake air box assy like is seen in the LT1 versions, both dry and wet sump.

If you have a LT1, then as it is naturallu aspirated, any time you accelerate, the intake manifold vacuum drops to zero and no evacuation takes place, so the crankcase will build pressure and it will vent backwards out the cleanside inlet and into your main intake air box assy and ingest via this path.

So the cleanside is needed in addition to the dual valve main separator

Why not defeat/delete the PCV system like some are selling that routes both the clean and dirty sides into a large tank and vent through breathers or open hoses hanging near the ground? Several reasons.

First would be the obvious, it will void your warranty in every case due to this will result in engine damage and premature wear of all internal engine parts from the damaging compounds now left to accumulate in the crankcase as evacuation has been defeated and these compounds are no longer removed.

Will not be legal on the street in any State, and will also fail emissions inspections.

What people need to realize is the PCV system provides several critical functions and only one is emissions related. When the Federal Gov mandated all cars and light trucks have CV systems in the mid 1960's, it was intended to reduce pollution, but what the automakers soon found was the engines that rarely lasted more that 50-60k miles before being entirely worn and in need of a total rebuild, were now lasting 100-150k plus miles and longer. Engineers soon found that when the PCV (positive crankcase ventilation) systems were in use, they were evacuating much more than just the oil mist/vapor. They also were constantly removing the water, unburnt fuel, sulfuric acid, abrasive soot and carbon particles, etc. that were previously left in the crankcase to contaminate the engine oil and further attack and corrode internal parts and flushing them with the filtered clean air entering the opposite bank as the foul vapors were evacuated from (evacuation is NOT venting. Venting can only bring a small fraction of these compounds out with pressure). So, defeating your PCV systems functions by using anything vented will result in engine damage and wear over time period. No possible way it cannot unless you would change oil after every outing, and that is impractical and costly.

Then, if it is a system with 2 hoses hanging down, you must understand how the Venturi Effect works. As air flows past an open hose or tube, it creates suction (this is the Venturi effect). But, since this is never equal, one hose will always become the stringer of the two with suction, and the opposite hose will turn into a vacuum cleaner so to speak and draw in dust/dirt/sand/water and other road debris (just look at how your engine bay gets covered in dust and sand in short order even driving on clean paved roads only) and this can enter the engine causing damage. Then we have to look at the fact that you have now bypassed the MAF sensor, and the factory tune is not going to be commanding fuel trims accurately, and you are also relying on pressure to first build instead of pulling vacuum at all times like the proper system will, so allowing any pressure to build to the point of venting out hoses or breathers will cause among many things, ring flutter. This over time results in "divots" of wear in the cylinder walls as well as on the rings themselves so they eventually do not, and cannot seal properly allowing even more blow-by.

So, for now I'll stop here and open this for questions. Do NOT be afraid to ask questions, your new Stingray is a sizable investment, and the engine is different than any of the previous port injection offerings, and these are things you need to be aware of to get the most with the least issues as far as engine related.

Looks like the same old problems to address with a catch can .

The charger lid off shows the oil accumulation on the blower.

The lid as well is covered .

The solution :

$975.00 installed

Available @ Dasilva Motorsports

Last edited: